Expect better

quality.

Since 1954, we’ve built a reputation as the quality mechanical contractors, mechanical service, and engineers in Kentucky. Lyons has the experience and expertise to design, construct, and service mechanical systems to meet your expectations of performance, craftsmanship, and budget. Don’t let poor quality sink your project.

Expect more.

Our service industries.

Expect better

service.

Whether optimizing an investment in new equipment or servicing existing systems, we provide flexible service solutions with support 24 hours a day, 7 days a week for equipment from all major manufacturers.

Expertise at your service.

Engineering

Our experienced engineering staff employs a ‘hands-on,’ practical approach to formulating recommendations, keeping constructability, maintainability, and economics at the forefront.

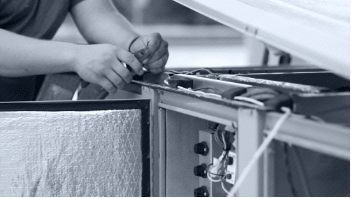

Mechanical Construction

We create solutions and solve problems in the mechanical systems that have significant impact on employee comfort, health, safety, manufacturing processes, and facility expenses.

Fabrication

Our fully-automated sheet metal shop utilizes the most advanced equipment to construct high-quality duct work and custom metal fabrication, ensuring indoor air quality and our customer’s satisfaction.

Building Automation Controls

We prioritize energy efficiency, customization, and open source as core tenants of service controls systems. Holding industry certifications and technical knowledge, our service technicians can repair, maintain, retrofit, bas controls to fit our your needs.

Mechanical Service

Our program of computer-interfaced preventive maintenance ensures our customers enjoy the greatest possible degree of trouble-free heating and air conditioning service.

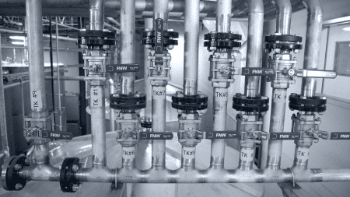

Custom Pipe Fabrication

Our pre-fabrication facility can provide the components you need from concept to installation. Pump headers, valve manifolds, spool pieces, whatever you need.

We built our reputation with a proven track record of consistently meeting customer expectations for quality mechanical contracting and service. Serving Southern Kentucky for over 65 years.

Our Legacy

Expect more.

Get more.

We deliver with over 65 years of experience and the expertise to design, construct, and service mechanical systems to meet your expectations of performance, craftsmanship, and budget.

Quality. Service. Expertise.

Let’s get started by filling out the form to the right. We’ll contact you to learn more about your project and equipment needs, then build a no-obligation proposal to show how valuable Lyons Company can be as part of your build team.

Let's talk

After we get some information from you, we’ll set up a time to discuss your project in further detail.